摘 要

本文主要对烘干机的设计,烘干机关键工序之一是烘干过程中即采取高温措施,又使新鲜食品内含物迅速地转化,使其水份充分挥发体积缩小。

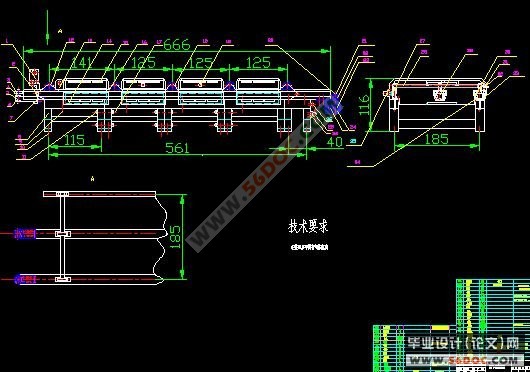

烘干机技术依据导热介质不同可分为金属导热,蒸气导热,空气导热,采用不同的导热介质可烘干不同的原料。

滚筒烘干机是利用金属导热连续烘干的设备,原料由送料斗送入温度为200°

~280°C的滚筒内随着筒内导叶板的作用,产生滚筒翻滚抛扬和前进三种运动,在筒内热空气及筒壁,原料的接触下,表面和内细胞的水分迅速汽化。

本产品主要对零件进行烘干,但是也可以通过改变夹具对对其他一些物体进行烘干。属于一种多功能机器,

通过对烘干机的设计,使三年所学的机械专业知识在实践中加深了认识,并且相当于进行了一次全面性的复习。

Abstract

This text mainly to the design which dries a heat of machine, dry one of a heat of organization key work prefaces dries to namely adopt heat measure in the process, and then makes the fresh food contain a thing to convert quickly and make its water well vaporize a physical volume to contract.

The dryer technique can is divided into metals to transmit heat according to transmitting heat to lie a quality dissimilarity and the fume transmit heat, the air transmit heat, and adopting to differently transmit heat to lie quality can dry different raw material.

The roller dryer is in a row the equipments which makes use of metals to transmit heat to dry, raw material from send to anticipate Dou to send into the temperature as 200 °s

~Inside the roller of 280 ° Cs along with tube inside lead a leaf knothole function, the creation roller is vacillating to throw Yang and go forward three kinds of sport, at the hot air inside the tube and the tube wall, raw material of under the contact, surface with inside the humidity of cell quickly vaporizes.

This product mainly carries on dry to the electronics plank, but can also pass change tongs to as to it's he some objects carry on dry.Belong to a kind of multi-function machine,

Pass to the design which dries a heat of machine, make the machine professional knowledge that three years learn deepen understanding in the fulfillment, and equal to carried on to comprehensively review at a time.

课题来源

烘干机在消化吸收了国外同类产品的技术优点的基础上,结合我国国情而最新开发的又一种新机型。本机能广泛应用于广播、电视、通讯、计算机、传真机、仪器、仪表等行业的印制线路板焊接过程。特别是本机能适用于贴片元件、集成电路与分立元件混装的印制线路板,是表面直查按装工艺中自动生产线里所不可缺少的专用设备,它具有轻巧灵活、调整方便、通用性强等特点,能满足板宽在200mm以下的各种批量件的生产。在整机性能上,已达到了国外同期同档次机型的水平,而价格实惠, 是目前替代进口设备的最佳选择.

目录

目录 I

第一章 前言 1

1.1 课题来源及意 1

1.2 烘干机电子行业中的地位及趋势发展趋势 1

第二章 烘干机总体方案设计 2

2.1设计方案 2

2.2减速机构 4

第三章 烘干机机构的设计 5

3.1原始数据 5

3.2选择电动机的型号 5

3.4链条与链轮的选择 8

3.5 齿轮的设计及校核 11

(咨询QQ:306826066)

3.5.1齿面接触疲劳强度计算 11

3.5.2校核计算 11

3.6 轴的设计及校核 15

3.7 轴承的设计和校核 18

(毕业设计网 参考更多的毕业设计请到 www.papersay.com )

3.8 键的设计和校核 20

本送料机构中使用了3个平键联结和1个斜键,其中斜键起连接撞柄的作用,可以不做校核。 20

第四章 润滑密封与保养 22

4.1 润滑 22

本设计中的齿轮采用脂润滑,每隔10个工作日手工加一次脂,从而经常保持齿面的清洁。润滑脂采用钙基润滑脂中的2号,它具有抗水性好等优点,环境适用性强。 22

4.2 密封 22

4.3 保养 22

参考文献 28

结束语 29

外文翻译 30

中文原文 39 |